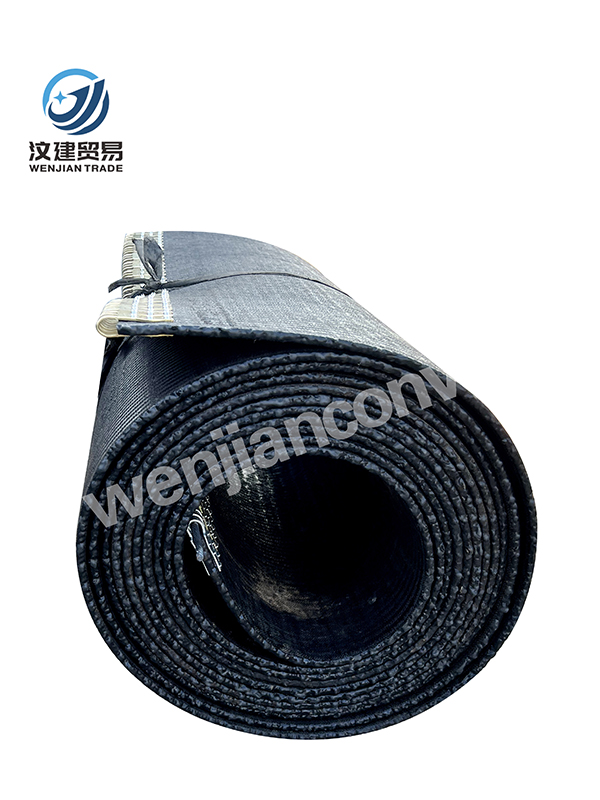

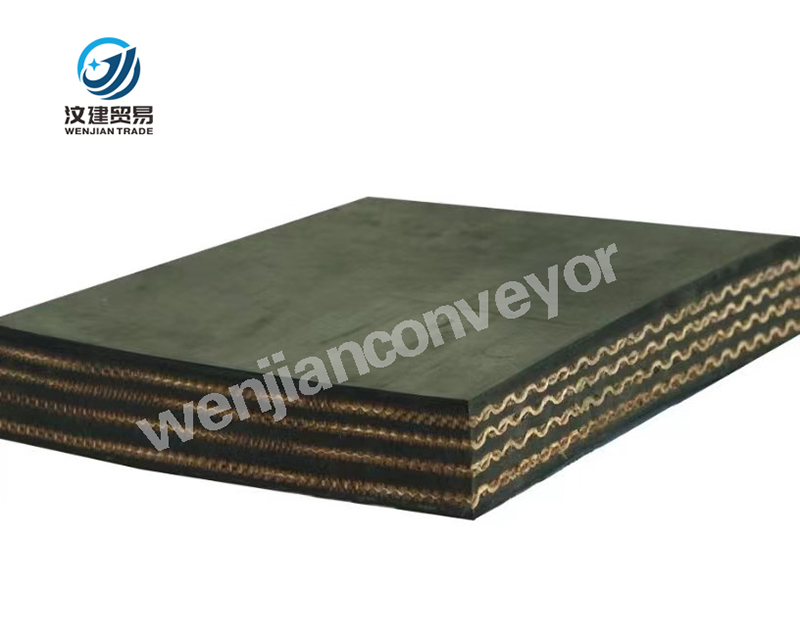

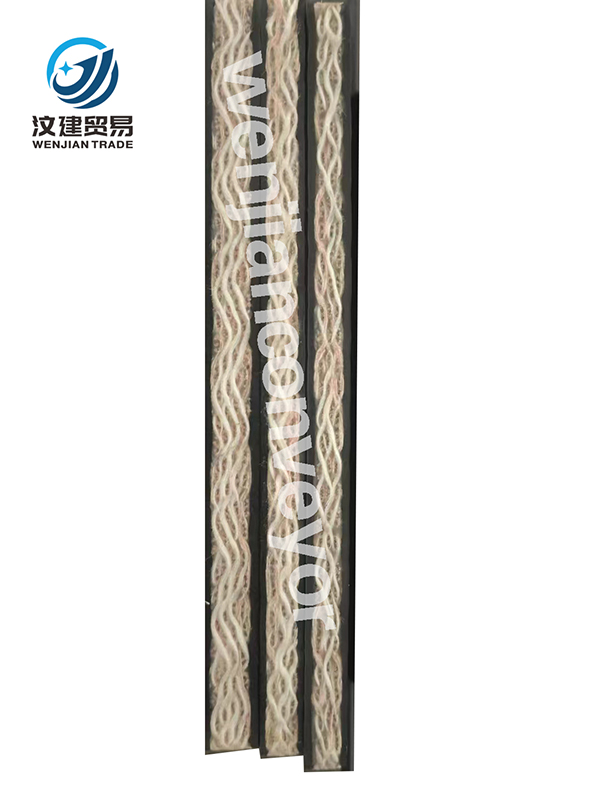

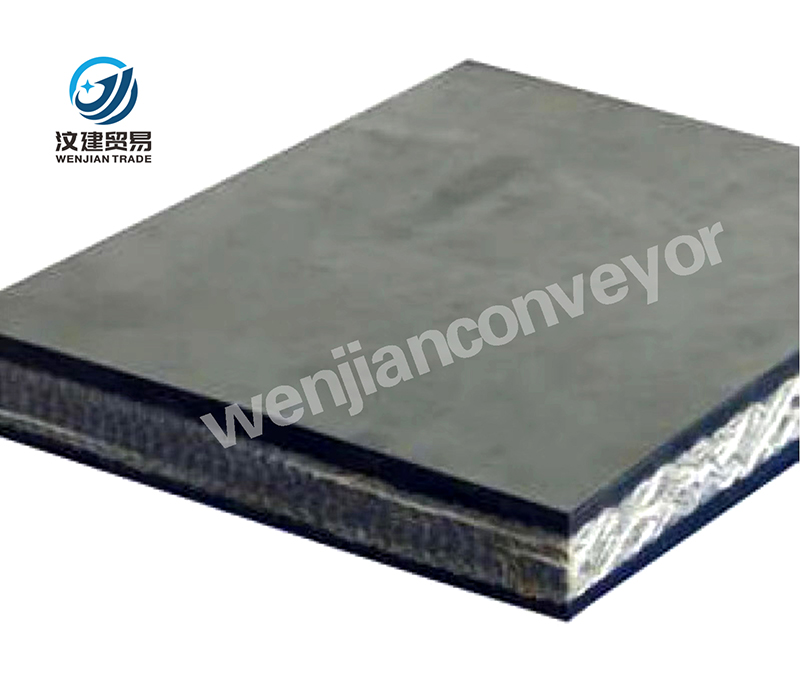

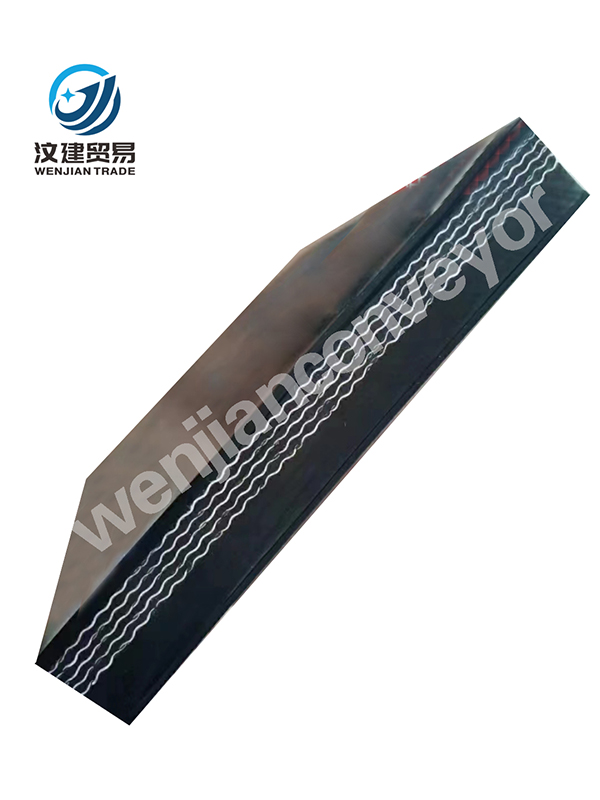

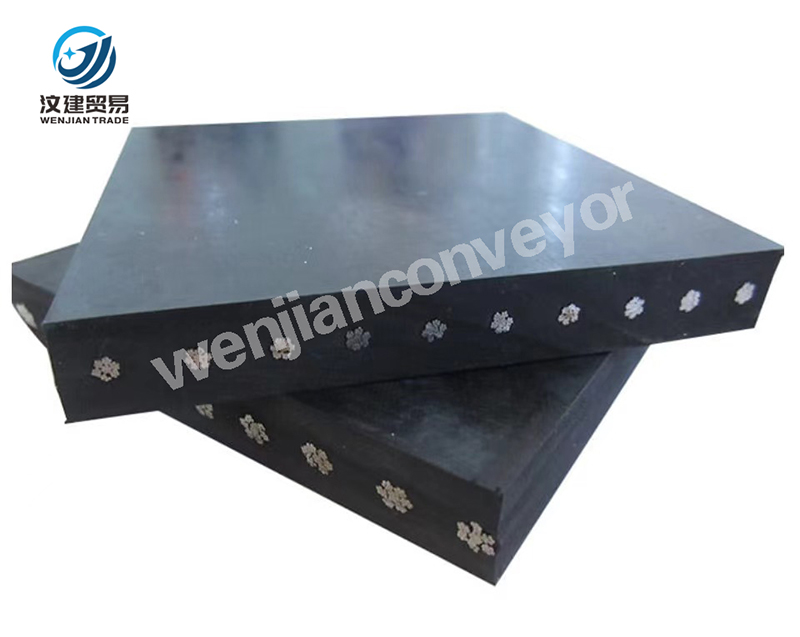

スチールコードコンベヤーベルト:高亜鉛メッキオープンスチールワイヤーロープは、さまざまな特別なニーズを満たすために使用されます. 高い柔軟性と低スライドのひもでつながれた鋼線ロープは、より高い接続効率を得ることができます. 読み取り鋼線ロープは、コア接着剤でしっかりと接着して、腐食の重要な保護層を形成することができます.

ソリッド専用鋼線ロープを採用. 単一の根は壊れていて高いです, そして重量は軽いです, これにより、コンベヤベルトの強度を高めて長距離搬送システムに対応できます.

定格張力下での鋼線コンベヤーベルトの伸びは、 0.25%. 多くのアプリケーションで, テンションが緩和されます, また、投資の削減は、長距離または低延長輸送の機会の最初の選択肢です.

ワイヤーロープのダイナミックな展示と強度が高い, また、ジョイントはコンベヤーベルトと同じ耐用年数を達成できます.

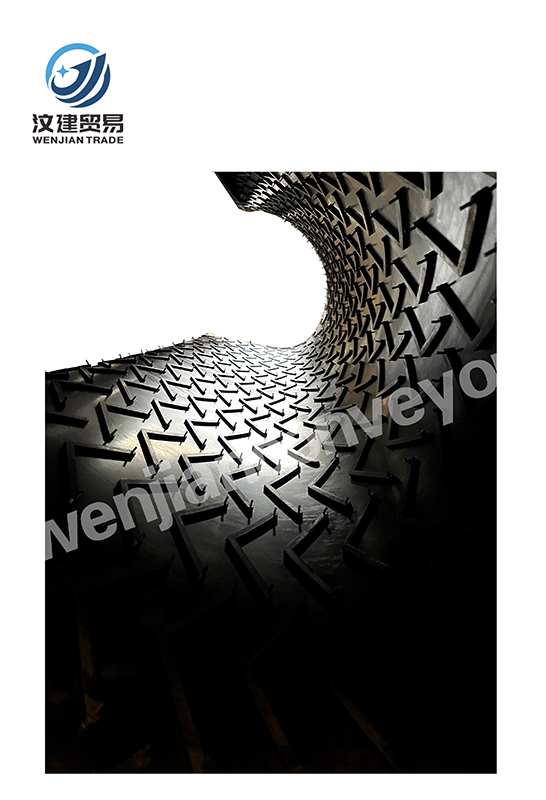

蓋と芯接着剤の優れた接着性能により、優れた耐衝撃性と耐引裂性が保証されます.

| スチールコードコンベアベルトの性能パラメータテーブル | ||||||||||||||||||||||

| モデル | ST500 | ST630の | ST800 | ST1000 | ST1250の | ST1400 | ST1600の | ST1800の | ST2000 | ST2250 | ST2500 | ST2800 | ||||||||||

| 引張強度 | 500 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1800 | 2000 | 2250 | 2500 | 2800 | ||||||||||

| 最大直径 | 3.0 | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 5.0 | 5.6 | 6.0 | 5.6 | 7.2 | 7.2 | ||||||||||

| 一般的な直径 | 2.8 | 2.8 | 3.0 | 3.4 | 3.8 | 4.4 | 4.4 | 4.6 | 5.0 | 5.2 | 6.6 | 6.6 | ||||||||||

| シングルルート強度 | 7.6 | 7.0 | 8.9 | 12.9 | 16.1 | 20.6 | 20.6 | 25.5 | 25.6 | 26.2 | 40.0 | 39.6 | ||||||||||

| スペーシング | 14 | 10 | 10 | 12 | 12 | 14 | 12 | 13.5 | 12 | 11 | 15 | 13.5 | ||||||||||

| カバレッジ レイヤーの最小厚さ | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 5 | 5 | ||||||||||

| コンベヤー

厚さ |

10.8 | 10.8 | 11 | 11.4 | 11.8 | 12.4 | 12.4 | 12.6 | 13 | 13.2 | 16.6 | 16.6 | ||||||||||

| 参考品質 | 15.0 | 16.0 | 16.5 | 17.0 | 18.0 | 19.5 | 20.0 | 20.5 | 22.0 | 23.5 | 29.0 | 30.0 | ||||||||||

| 幅 | 偏差 | 鋼鉄 W怒り Rオペ | ||||||||||||||||||||

| 500 | +10/-5 | 33 | 45 | 45 | 39 | 39 | 34 | 39 | ||||||||||||||

| 650 | +10/-7 | 44 | 60 | 60 | 51 | 51 | 45 | 51 | 46 | 52 | 56 | 41 | 46 | |||||||||

| 800 | +10/-8 | 54 | 75 | 75 | 63 | 63 | 55 | 63 | 57 | 63 | 69 | 50 | 57 | |||||||||

| 1000 | ±10 | 68 | 95 | 95 | 79 | 79 | 68 | 79 | 71 | 79 | 86 | 64 | 71 | |||||||||

| 1200 | ±10 | 83 | 113 | 113 | 94 | 94 | 82 | 94 | 85 | 94 | 104 | 76 | 85 | |||||||||

| 1400 | ±12 | 96 | 133 | 133 | 111 | 111 | 97 | 111 | 100 | 111 | 122 | 89 | 99 | |||||||||

| 1600 | ±12 | 111 | 151 | 151 | 126 | 126 | 111 | 126 | 114 | 126 | 140 | 101 | 114 | |||||||||

| 1800 | ±14 | 125 | 171 | 171 | 143 | 143 | 125 | 143 | 129 | 143 | 159 | 114 | 128 | |||||||||

| 2000 | ±14 | 139 | 191 | 191 | 159 | 159 | 139 | 159 | 144 | 159 | 177 | 128 | 143 | |||||||||

| 2200 | ±15 | 153 | 211 | 211 | 176 | 176 | 154 | 176 | 159 | 176 | 195 | 141 | 158 | |||||||||

| 上覆 Lアイヤー Pハイジカル Pロペティ | ||||||||||||||||||||||

| パフォーマンス | 引張強度/Mpa | 破断点伸び/% | 研削速度/mm3 | |||||||||||||||||||

| H | 24 | 450 | 120 | |||||||||||||||||||

| D | 18 | 400 | 100 | |||||||||||||||||||

| M | 15 | 350 | 200 | |||||||||||||||||||

| H:バンドに強い損傷を与える鋭利な研磨材の輸送に使用されます;D:高摩耗材料の輸送に使用;M:適度な摩耗材の搬送に使用 | ||||||||||||||||||||||

ウェンジャン

ウェンジャン