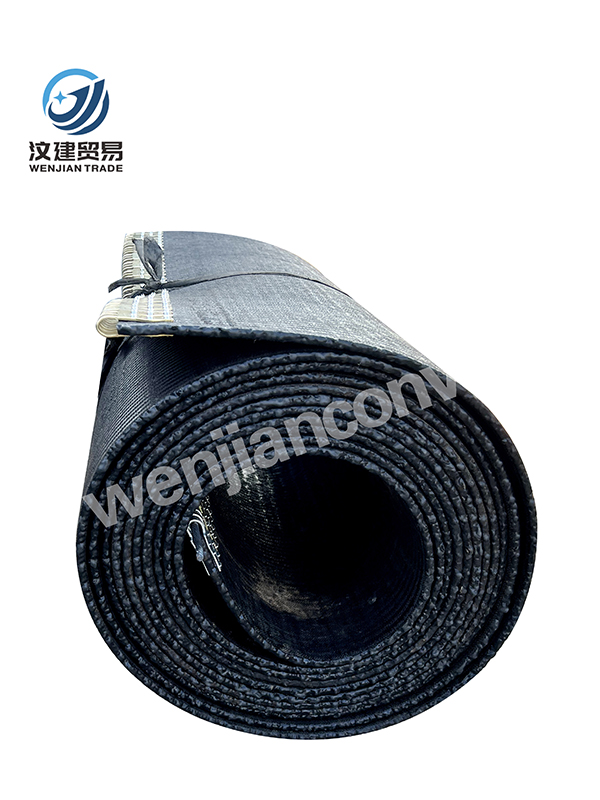

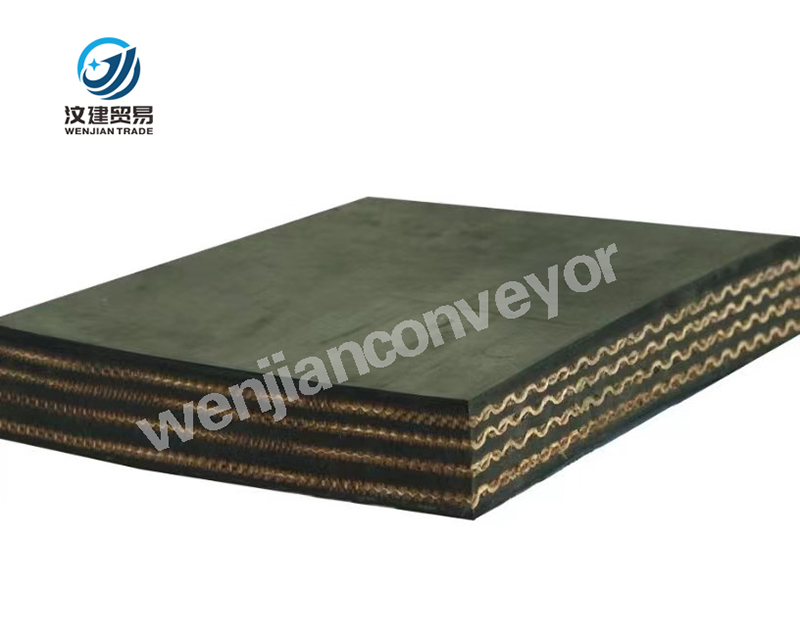

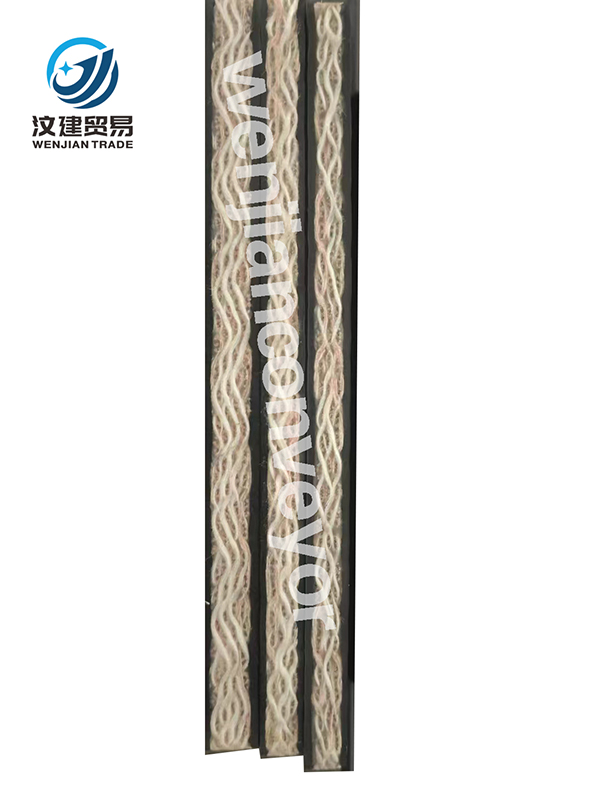

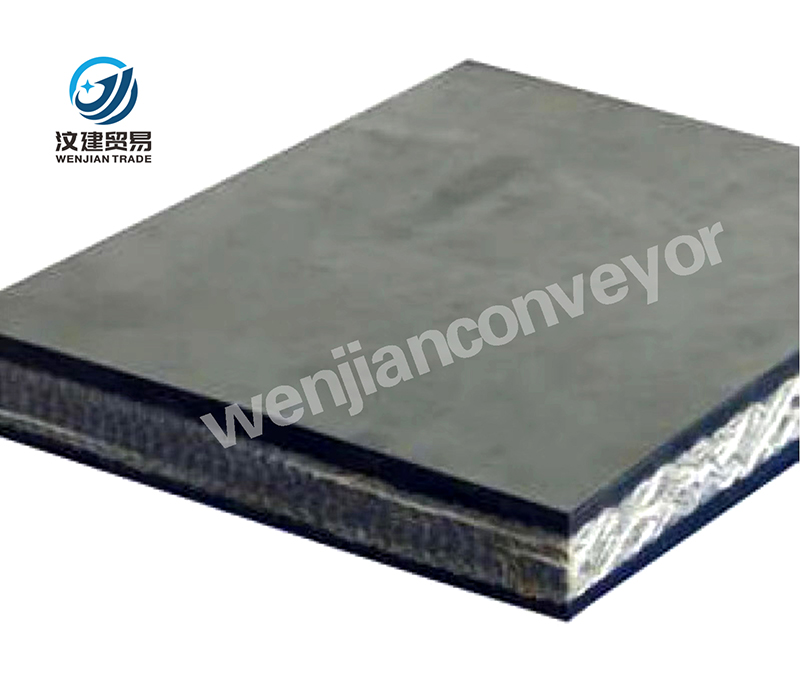

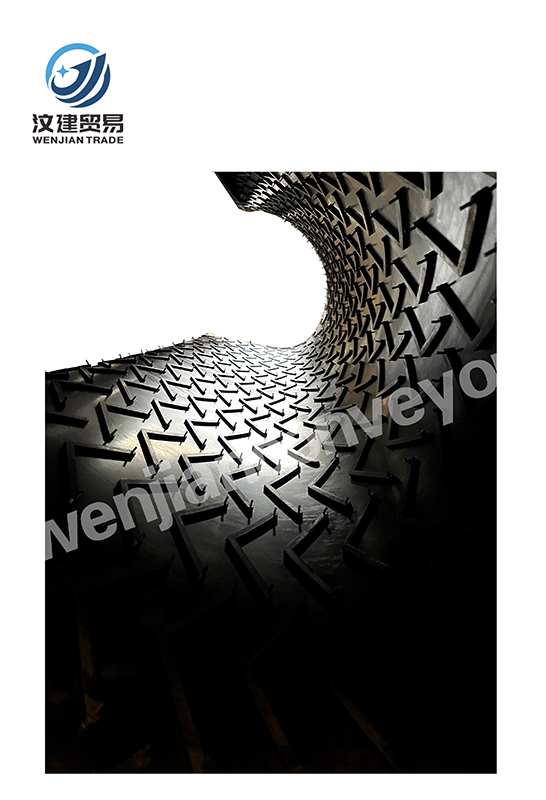

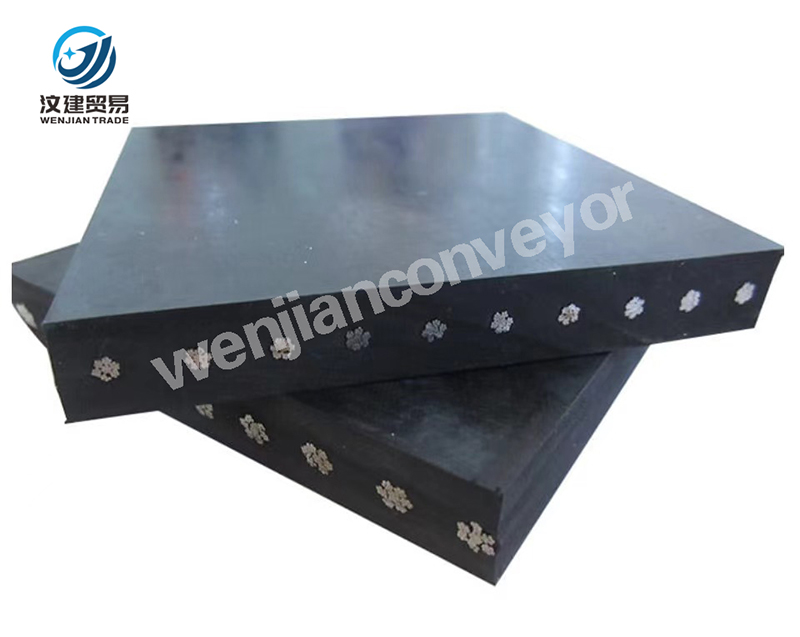

Конвейерная лента со стальным кордом:Высокооцинкованный открытый стальной канат используется для удовлетворения различных специальных потребностей. Высокая гибкость и низкое скольжение струнного стального троса позволяют повысить эффективность соединения. Стальной трос для чтения может быть плотно скреплен сердечным клеем для образования важного защитного слоя от коррозии.

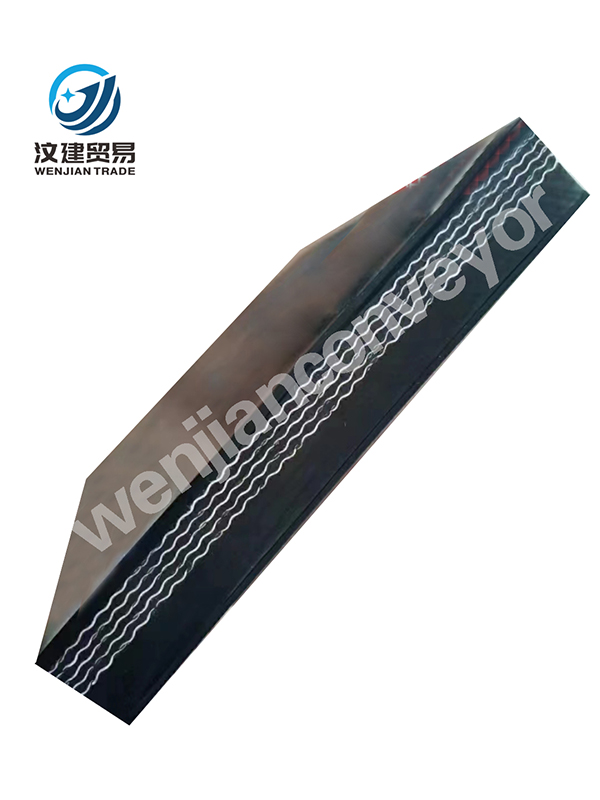

Используется прочный стальной канат. Одиночные корни сломанные и высокие, да и вес легкий, что может увеличить прочность конвейерной ленты для соответствия системе транспортировки на большие расстояния.

Удлинение конвейерной ленты из стальной проволоки под номинальным напряжением составляет 0.25%. Во многих приложениях, напряжение снижается, и сокращение инвестиций является первым выбором для перевозок на дальние расстояния или с небольшой протяженностью.

Динамическая демонстрация каната и высокая прочность, и шарниры позволяют достичь того же срока службы, что и конвейерная лента.

Превосходные адгезионные свойства крышки и клея для сердцевины обеспечивают хорошую ударопрочность и прочность на разрыв.

| Таблица эксплуатационных параметров конвейерной ленты со стальным кордом | ||||||||||||||||||||||

| Модель | СТ500 | ст630 | ст800 | ст1000 | ст1250 | ст1400 | ст1600 | ст1800 | ст2000 | ст2250 | ст2500 | ст2800 | ||||||||||

| Прочность на разрыв | 500 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1800 | 2000 | 2250 | 2500 | 2800 | ||||||||||

| Максимальный диаметр | 3.0 | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 5.0 | 5.6 | 6.0 | 5.6 | 7.2 | 7.2 | ||||||||||

| Общий диаметр | 2.8 | 2.8 | 3.0 | 3.4 | 3.8 | 4.4 | 4.4 | 4.6 | 5.0 | 5.2 | 6.6 | 6.6 | ||||||||||

| Однокорневая прочность | 7.6 | 7.0 | 8.9 | 12.9 | 16.1 | 20.6 | 20.6 | 25.5 | 25.6 | 26.2 | 40.0 | 39.6 | ||||||||||

| Интервал | 14 | 10 | 10 | 12 | 12 | 14 | 12 | 13.5 | 12 | 11 | 15 | 13.5 | ||||||||||

| Минимальная толщина слоя покрытия | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 5 | 5 | ||||||||||

| Конвейер

Толщина |

10.8 | 10.8 | 11 | 11.4 | 11.8 | 12.4 | 12.4 | 12.6 | 13 | 13.2 | 16.6 | 16.6 | ||||||||||

| Эталонное качество | 15.0 | 16.0 | 16.5 | 17.0 | 18.0 | 19.5 | 20.0 | 20.5 | 22.0 | 23.5 | 29.0 | 30.0 | ||||||||||

| Ширина | Отклонение | Сталь Втгнев RОПЕ | ||||||||||||||||||||

| 500 | +10/-5 | 33 | 45 | 45 | 39 | 39 | 34 | 39 | ||||||||||||||

| 650 | +10/-7 | 44 | 60 | 60 | 51 | 51 | 45 | 51 | 46 | 52 | 56 | 41 | 46 | |||||||||

| 800 | +10/-8 | 54 | 75 | 75 | 63 | 63 | 55 | 63 | 57 | 63 | 69 | 50 | 57 | |||||||||

| 1000 | ±10 | 68 | 95 | 95 | 79 | 79 | 68 | 79 | 71 | 79 | 86 | 64 | 71 | |||||||||

| 1200 | ±10 | 83 | 113 | 113 | 94 | 94 | 82 | 94 | 85 | 94 | 104 | 76 | 85 | |||||||||

| 1400 | ±12 | 96 | 133 | 133 | 111 | 111 | 97 | 111 | 100 | 111 | 122 | 89 | 99 | |||||||||

| 1600 | ±12 | 111 | 151 | 151 | 126 | 126 | 111 | 126 | 114 | 126 | 140 | 101 | 114 | |||||||||

| 1800 | ±14 | 125 | 171 | 171 | 143 | 143 | 125 | 143 | 129 | 143 | 159 | 114 | 128 | |||||||||

| 2000 | ±14 | 139 | 191 | 191 | 159 | 159 | 139 | 159 | 144 | 159 | 177 | 128 | 143 | |||||||||

| 2200 | ±15 | 153 | 211 | 211 | 176 | 176 | 154 | 176 | 159 | 176 | 195 | 141 | 158 | |||||||||

| Покрытие ЛАйер PГигиенические PРопертис | ||||||||||||||||||||||

| Производительность | Прочность на разрыв/МПа | Относительное удлинение при разрыве/% | Скорость помола/мм3 | |||||||||||||||||||

| ЧАС | 24 | 450 | 120 | |||||||||||||||||||

| D | 18 | 400 | 100 | |||||||||||||||||||

| M | 15 | 350 | 200 | |||||||||||||||||||

| ЧАС:Используется для транспортировки резко абразивных материалов, имеющих сильные повреждения ленты;D:Используется для транспортировки износостойких материалов;M:Используется для транспортировки материала с умеренным абразивным износом | ||||||||||||||||||||||

Вэнь Цзянь

Вэнь Цзянь